About us

The Pan-Asia Youth Collaborative Academic Team on Lifetime and Reliability (PYCAT-LR) is committed to establishing an international academic ecosystem for emerging scholars. Guided by our motto “Agile Minds Leading Revolution”, we foster cutting-edge collaborative innovation in system lifespan prediction and reliability engineering among Asia’s new generation researchers. Through cross-border multidisciplinary dialogues, we build open knowledge networks to cultivate globally-minded young academic leaders, collectively addressing fundamental challenges in complex system lifecycle management. Focusing on the developmental needs of scholars under 40, we create comprehensive collaboration frameworks encompassing theoretical breakthroughs, technological innovations, and engineering applications, injecting sustained vitality into reliability science advancement.

Research background

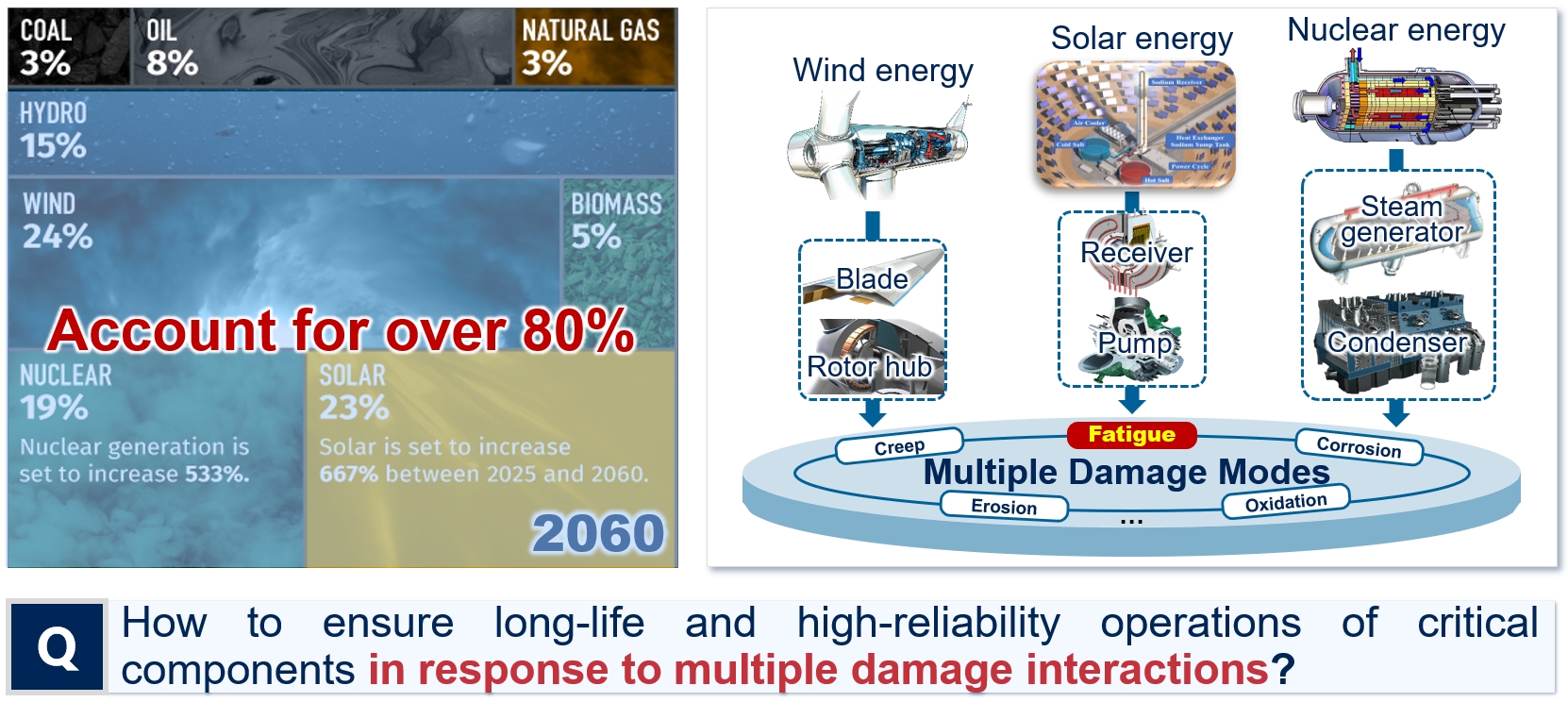

As we know, increasing the percent of clean energy sources is an effective path for carbon reduction. It is expected that the clean energy sources, including nuclear, wind, will account for over 80% of the energy mix by 2060. However, one of the key challenges during clean energy transition is how to ensure the long-life and high-reliability operations of critical components in the energy systems. These components, may undergo multiple damage interactions along with time, such as fatigue, corrosion, and thermal effects. Especially, fatigue-dominated damage will have an obvious effect on the structural integrity and reliability of the critical components or systems. Hence, how to develop methods to predict and mitigate these damages becomes more important.

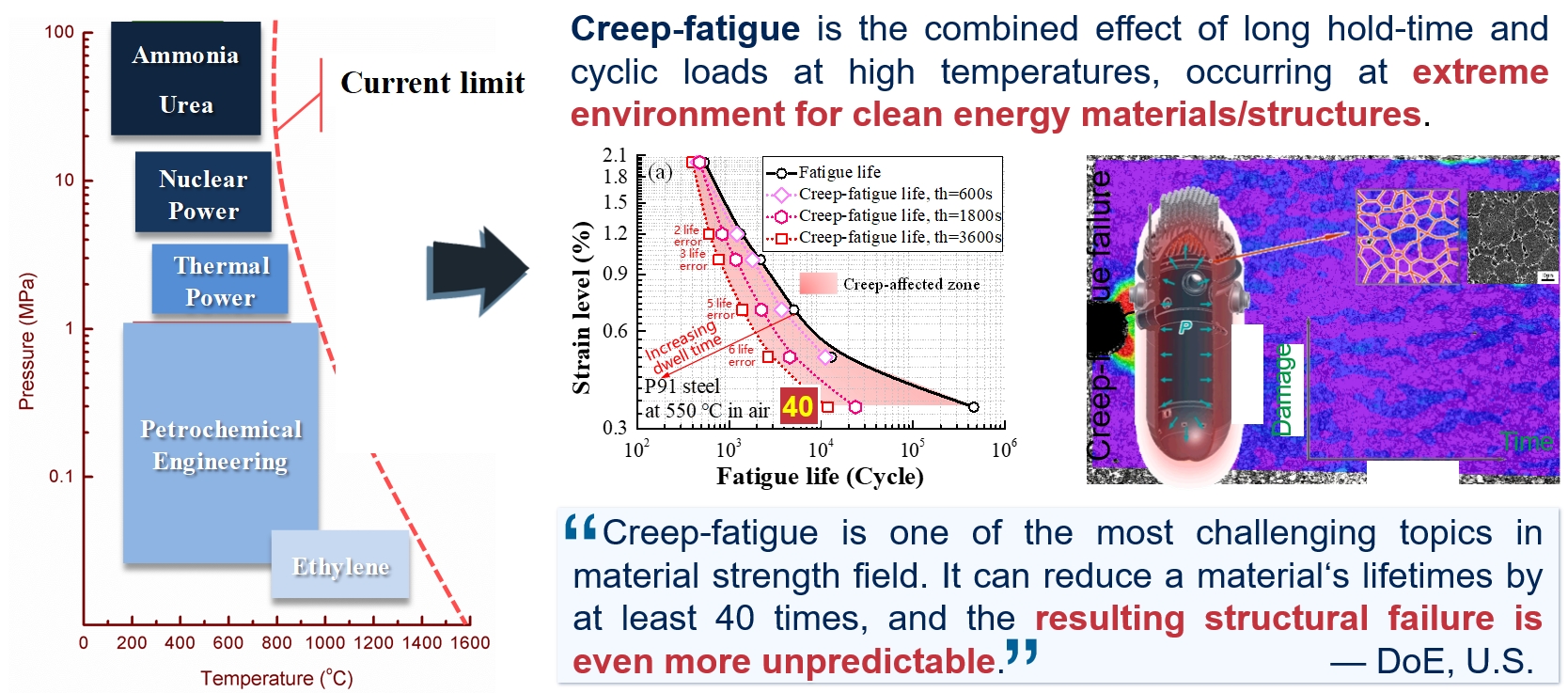

There is the current limit for design under different industrial fields, namely with increasing the working temperatures, the allowable pressure would be decreased. But a lot of components used at high temperature with undergo the multiple damage, especially creep and fatigue interaction. Creep-fatigue occurs when components experience both prolonged stress at high temperatures and cyclic mechanical loads. This interaction will accelerate material degradation, often leading to early failures. For instance, in materials like P91 steel, creep-fatigue can reduce the lifetime by a large number of scatters by comparing with pure fatigue. According to DoE, U.S.:” Creep-fatigue is one of the most challenging topics in material strength field. It can reduce material lifetimes by at least 40 times, and the resulting structural failure is even more unpredictable.”

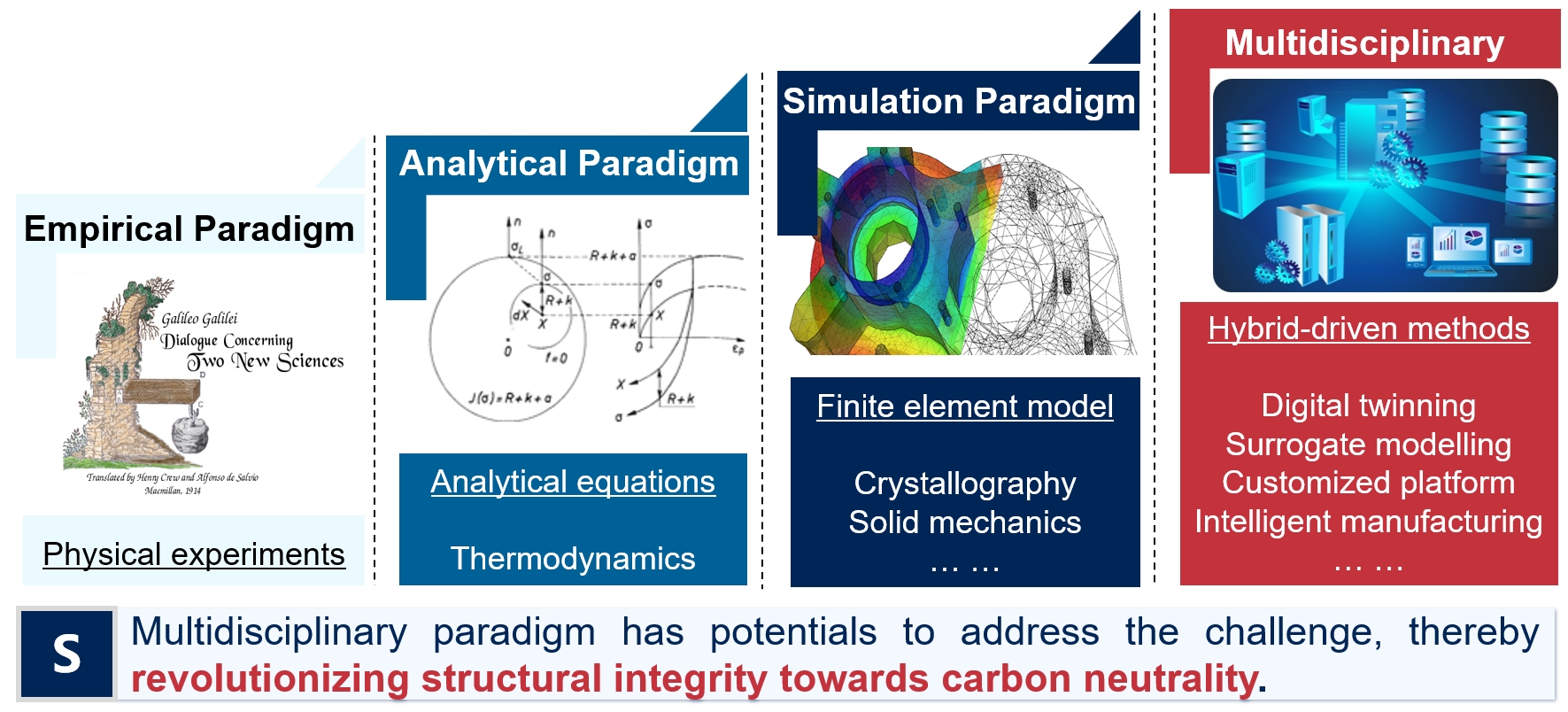

On the other hand, Galileo’s Dialogue Concerning Two New Sciences, made the beginning of the development of strength science. Over the past 300 years, strength science to ensure “safety” has evolved through different paradigms, namely Empirical Paradigm including Physical experiments, Analytical Paradigm including analytical model, Simulation Paradigm including finite element modeling. Now, the multidisciplinary paradigm, namely hybrid driven methods, including digital twinning and surrogate modeling, is being active.

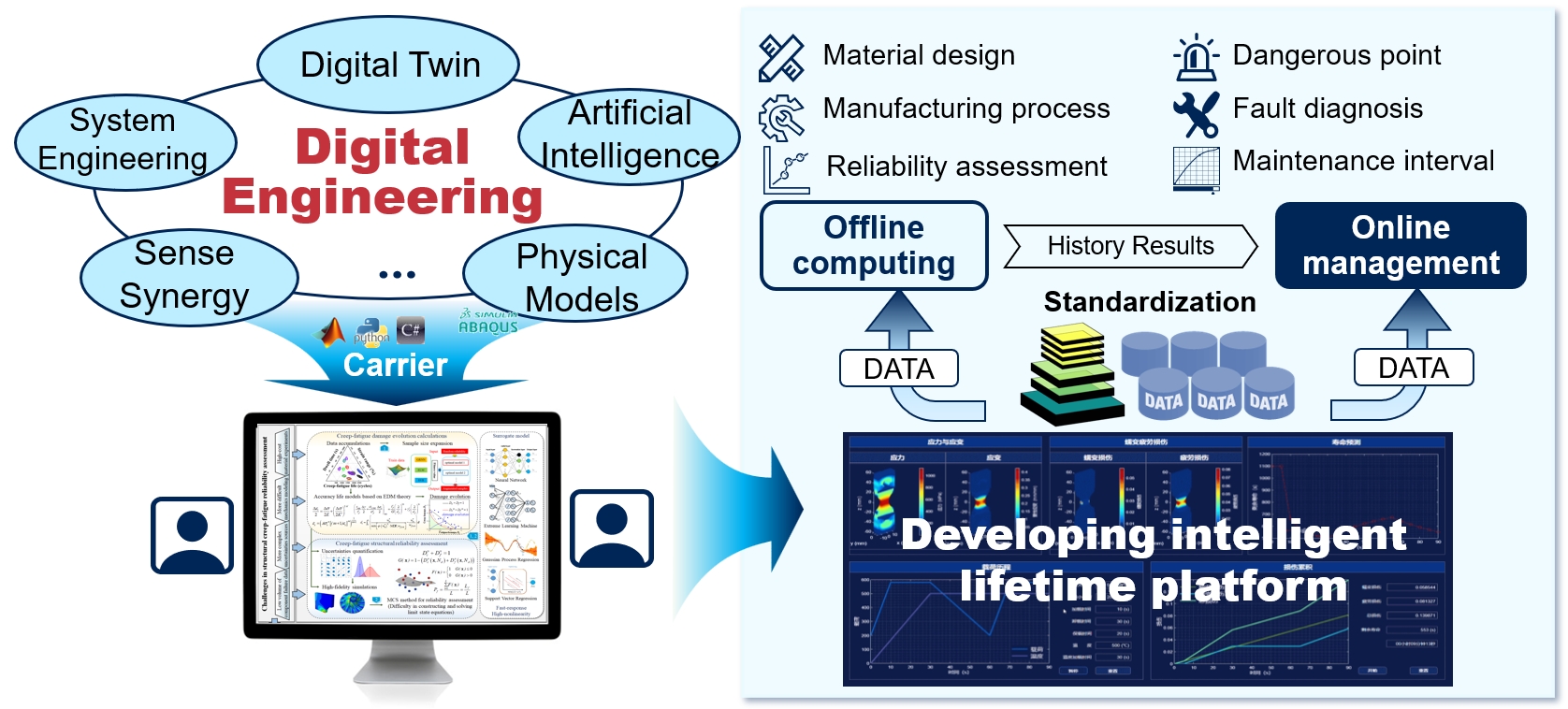

Additionally, we are advocating for digital engineering with a focus on “damage” as the core. This involves creating intelligent platforms that utilize digital twins, artificial intelligence, and system engineering to optimize material design, manufacturing processes, and maintenance intervals. A key aspect is the change from offline computing to online management.