A modified fatigue life prediction model considering residual stresses relaxation and microhardness distribution for surface strengthening materials

Author

Ling Ju, Kai-Shang Li*, Lv-Yi Cheng, Hang-Hang Gu, Run-Zi Wang, Xian-Cheng Zhang, Shan-Tung Tu

Periodical

International Journal of Fatigue

Abstract

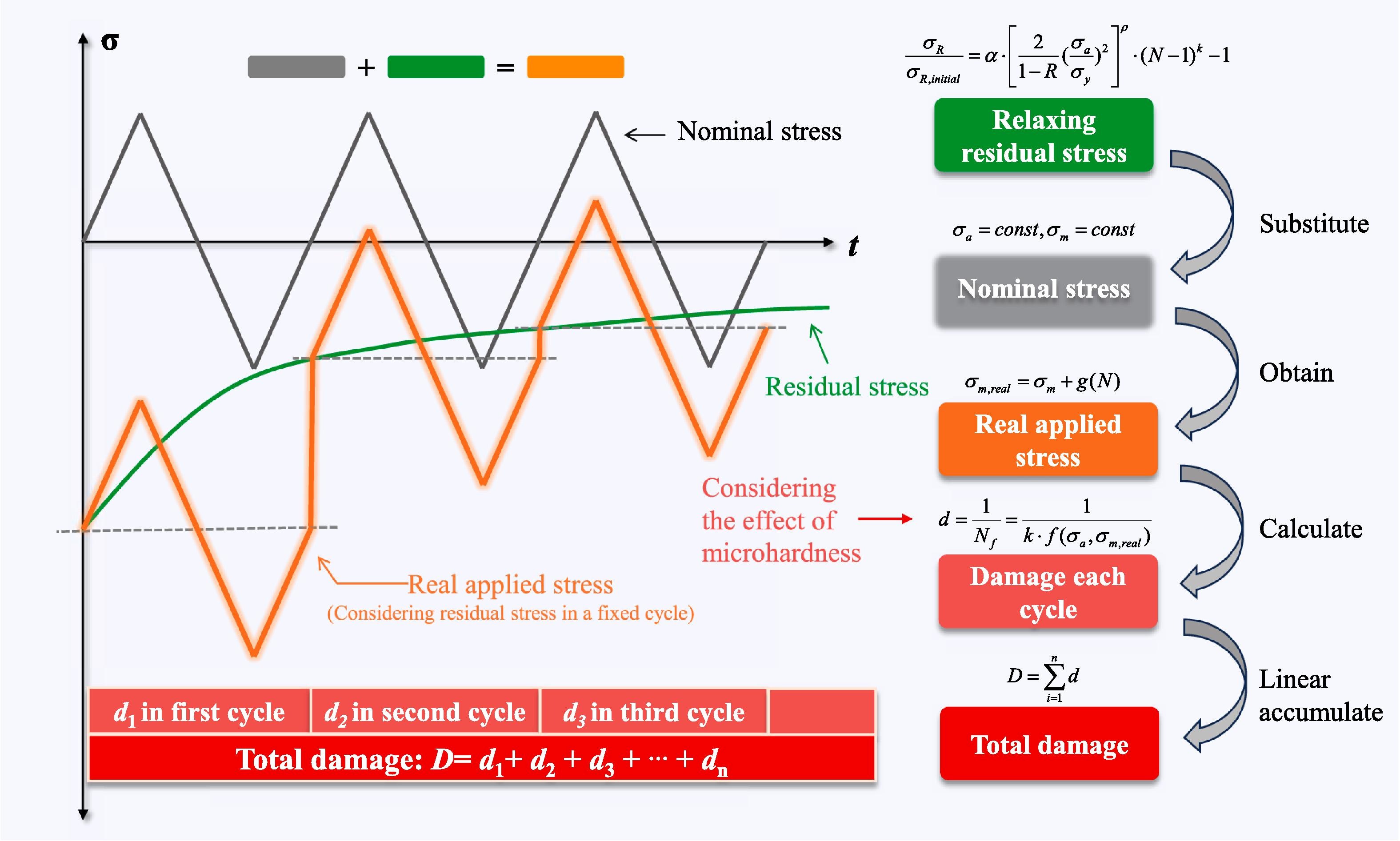

In this paper, a fatigue life prediction model of surface strengthening materials is proposed by considering dominant surface integrity parameters. The maximum residual stress and maximum microhardness of the surface strengthening materials are determined as the dominant parameters for the development of fatigue life prediction model according to the correlation analysis between surface integrity parameters and fatigue life. Firstly, an existing residual stress relaxation model is modified to characterize the relaxation process of residual stress with the number of cycles. Subsequently, a real applied stress on surface strengthening specimens is calculated by considering the effect of residual stress on the mean stress. The fatigue damage each cycle under the real applied stress that varies with cycles is calculated by introducing a correction factor related to the maximum microhardness. Finally, the fatigue life is predicted with the help of linear damage accumulation according to Miner’s rule. The developed model is verified on shot peened SS304, deep rolled TC4 and ultrasonic surface rolled TC4, exhibiting a good agreement with experimental results.

Keywords

Fatigue life prediction

Surface strengthening effect

Surface integrity

Residual stress

Microhardness

Figure