Transient liquid phase bonding of DD5 single crystal and GH4169 superalloy using BNi-2 interlayer: From microstructural evolutions to mechanical properties

Author

Xin Zhang, Kai-Shang Li*, Ning Yao, Jun-Miao Shi, Ti-Wen Lu, Wen-Rui Nie, Run-Zi Wang, Xian-Cheng Zhang, Shan-Tung Tu

Periodical

Materials Science and Engineering: A

Abstract

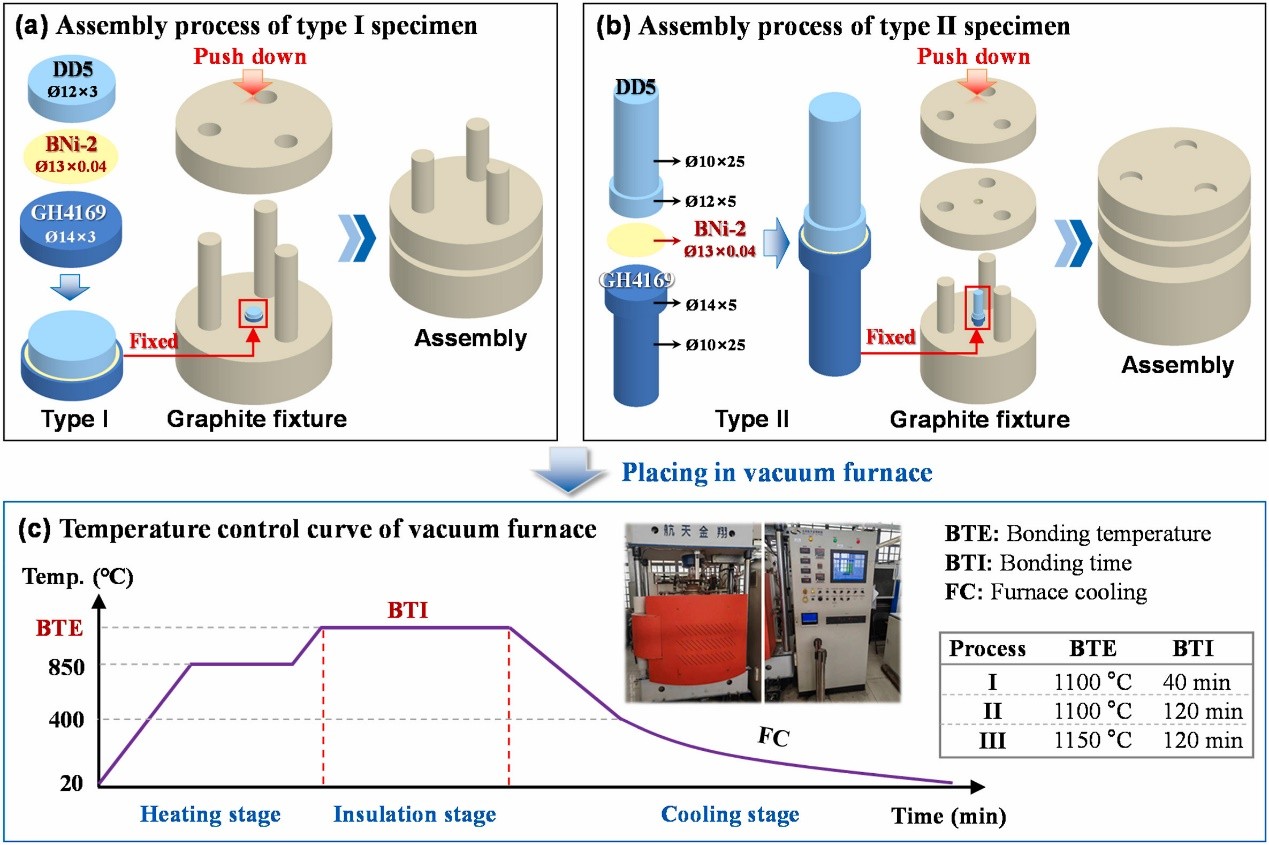

Diffusion bonding of dissimilar metals can lead to the formation of intermetallic compounds during the bonding process, which significantly compromise the mechanical properties of the bonded structures. A comprehensive understanding of both the formation and failure mechanisms of bonding joints is essential for optimizing the bonding process and enhancing mechanical properties. In this study, transient liquid phase (TLP) bonding of DD5 single crystal and GH4169 superalloy was conducted using a BNi-2 filler alloy. The effects of bonding temperature and time on the microstructural evolution and mechanical properties of the TLP joints were investigated. From the perspective of microstructure, distinct diffusion affected zone (DAZ) and isothermal solidification zone (ISZ) form in the TLP bonded joints. The widths of DAZ and ISZ increase with higher bonding temperature and time. Additionally, the size of the fine grains in the DAZ of GH4169 increases with bonding temperature and time, and boron (B) accumulates at the grain boundaries in the DAZ of GH4169. The formation sequence in the TLP bonding joint is found to be (i) melting of BNi-2 filler alloy, (ⅱ) formation of M5B3-type precipitations, followed by (ⅲ) isothermal directional solidification from the DD5 side to the GH4169 side, and (ⅳ) formation of the γ solid solution. In terms of mechanical properties, the microhardness decreases gradually from the GH4169 side to the ISZ and stabilizes from the ISZ to the DD5 side. The specimen bonded at 1100 °C for 120 min exhibited the highest tensile strength (928.63 MPa) and fracture strain (1.62 %) among three TLP bonding processes, achieving 86.8 % of the tensile strength and 51.7 % of the fracture strain of the BM of DD5. The failure mechanisms of the tensile specimens after different TLP bonding processes were explored with the aid of microstructural observations. This study provides valuable insights and technical support for achieving the reliable bonding between DD5 single crystal with GH4169 superalloy.

Keywords

Transient liquid phase bonding

Microstructural evolution

Mechanical property

Nickel-based superalloy

Figure