Interfacial characteristics and microstructural evolution of austenitic to ferritic stainless steels bimetallic structure fabricated by wire-arc directed energy deposition

Author

Yipu Xu, Run-Zi Wang*, Yutaka S Sato, Shun Tokita, Yue Zhao, Zongli Yi, Aiping Wu

Periodical

Abstract

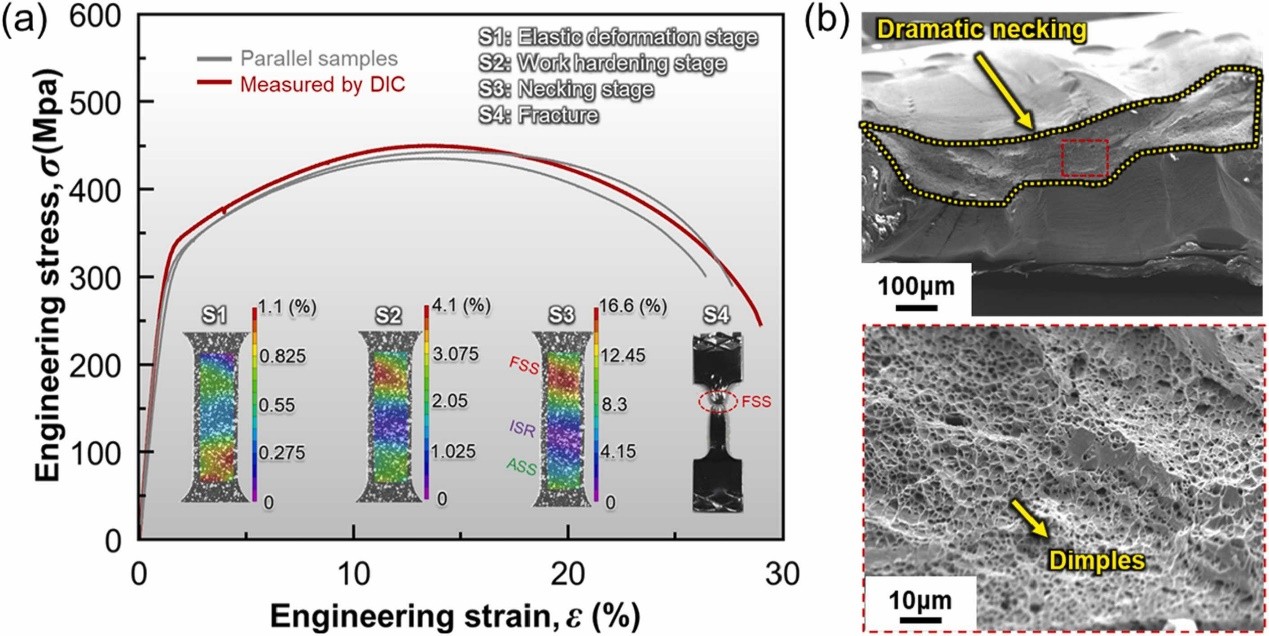

Additive manufacturing (AM) has emerged as a promising approach for producing bimetallic components with tailored site-specific properties. In this work, a bimetallic structure of 304 austenitic stainless steel (ASS) and 430 ferritic stainless steel (FSS) is fabricated using wire-arc directed energy deposition (DED) process. The interfacial characteristics of bimetallic additively manufactured structure are extensively revealed based on microstructural observations and mechanical performance assessments. The interfacial microstructure exhibits a distinct morphology with the ASS region and FSS region. Numerous lathy α’-martensite and dendritic α’-martensite make contributions on a sharp increase of hardness and tensile strength in the interfacial region. Afterwards, the microstructural evolution at the interface is further elucidated in view of elemental diffusion behavior and thermal cycles. During remelting at the interface, γ-stabilizer elements migrate from the ASS side to the FSS side, which promotes the martensitic transformation when quenching into ambient temperature. This investigation provides insights for further compositional gradients design and parametric optimization in wire-arc DED process.

Keywords

Directed energy deposition

Interfacial characterization

Microstructural evolution

Mechanical property

Bimetallic structure

Figure